Fabrikes – Olive Mills in Pediada

Author Discover Crete

Culture

Culture

The olive groves of the Pediada region give the landscape a distinct charm. Olives remain a driving force of the local economy in the Municipality of Minoa Pediada. They’re harvested with effort and care. The ones that aren’t eaten end up in the olive mills, where they’re turned into Crete’s liquid gold: olive oil.

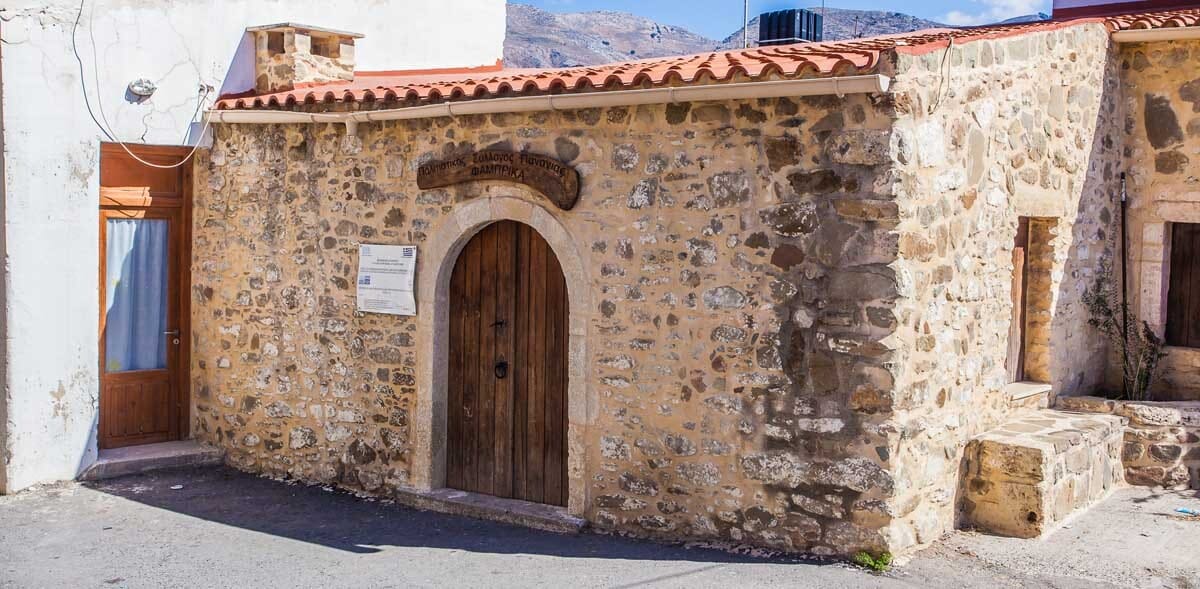

Before today’s modern mills, every village in the region had its own "fabrika" — the old-style olive presses. Most of these are now abandoned, slowly giving in to time. In Crete, these olive mills were known as "fabrikes". They were simple stone buildings with either tiled or flat roofs, often with the owner’s home on the upper floor. They could be privately owned, or run by cooperatives or monasteries. The oil extraction process was tough and done in three stages: crushing the olives, pressing the pulp, and separating the oil.

The first step took place inside the fabrika: crushing the fruit. Over time, the fabrikes went through two major technological shifts. The older type used a single millstone with wooden internal parts. The newer model, introduced in the early 20th century, used three or four stones. It had a more complex design, with metal moving parts, and it crushed olives into pulp more efficiently and quickly.

Animal power was key to keeping the fabrika going. Oxen, mules or horses were used to move the stone. The millstone was attached to a vertical wooden shaft, the "axoni", which turned inside a basin — the "aloni" — filled with olives. The axoni was fixed to a horizontal wooden beam, the "zygos", which was tied to the animal. As the animal walked in circles around the basin, it made the stone roll over the olives and crush them into pulp.

The second stage was pressing this pulp using a large screw press, first made of wood, later of iron. The pulp was packed into sacks, stacked five to seven high at the base of the press. These were then pressed three times, using pure muscle power to turn the screw with a wooden beam. The first pressing produced the "adolon" or virgin oil. For the second and third pressings, boiling water was poured over the sacks to extract the remaining oil. This would then be collected in a container.

Source: Municipality of Minoa Pediada